Flashing application requirements are similar for all types of low slope roof materials and systems.

Low slope roofing supply flashing.

1 cover the entire surface with a self adhesive flashing membrane such as grace ice water shield there are many.

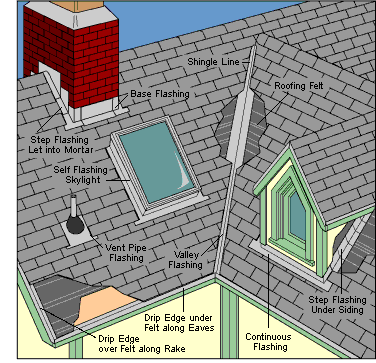

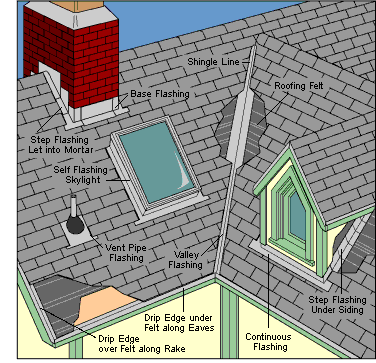

If this is a repair job the siding must also be removed and replaced with the flashing.

Iko roof fast base ma is a fiberglass reinforced nailable base with a special film surface designed to be used as one of iko s roof fast low slope roofing components.

Normally used with a low slope.

Sections of flashing shall have an end lap of not less than 4 inches 102 mm.

Second step flashing needs to extend 8 to 14 inches above the shingles according to the national roofing contractors association nrca.

Roof flashing shall be not less than no.

Low slope roof slip metal flashing for the roofing industry is available in standard 10 lengths from sheet metal supply.

The primary similarity is that flashings require total adhesion to the membrane and substrate.

26 gage 0 019 inches 0 5 mm corrosion resistant sheet metal and shall extend 10 inches 254 mm from the centerline each way for roofs having slopes less than 12 units vertical in 12 units horizontal 100 percent slope and 7 inches 178 mm from the centerline each way for slopes of 12 units vertical in 12 units horizontal and greater.

For a low slope residential roof there are two main options.

In combination with iko roof fast cap sheets it provides waterproofing properties and durability for low slope roofs.

Low slope metal roofing materials include perimeter edge flashing soffit panels drainage and es 1 rated edge systems from sheet metal supply.

Photo courtesy of johns manville.

First step flashing must be installed before the siding so that the siding can cover the top of the flashing.

Installation of flashing should be completed in accordance with the manufacturer s latest printed specifications.